At Hagans Plastics Co., Inc., we have met the growing demands of our customers through our advanced technology in tooling, manufacturing, production, and most importantly, quality.

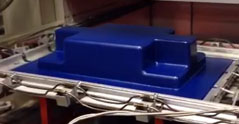

Our thermoforming capabilities are the cornerstone at Hagans Plastics and represent over 40 years of commitment to producing parts and components with unsurpassed quality.

Right from the start in 1973, our goal has been to make what others said could not be done. As a full-service custom thermoformer and injection molder, we provide parts to a diverse customer base. Hagans Plastics has supplied parts from those used on the space station to the making of the Chuck E. Cheese costume head. This diversity has given us years of experience in working with all types of customers from large corporations, government, to the small inventor with an idea. Everyone is treated as our most important customer because they all are.

Hagans Plastics believes in investing in the future. With our AS9100 and our ISO 9001 certification, we have put the steps into the process required that ensure that we not only meet but exceed all your expectations. It is our commitment to our customers that we constantly improve not only our equipment but our processes and technology.

Hagans Plastics wants to make sure that each and every customer is treated like they are our most important customer; why, because they are. Whether you are an established company with a host of engineers, or a individual with a GREAT new idea, we want you to be successful. Follow along in our process from start to finish to see what goes into getting your product from concept to market.

Customers

While the majority of our customer base is located within the United States, our quality products are manufactured for customers located in 7 countries, such as Germany, France, Mexico, China, Canada, Malaysia, Brazil

Community Service

TEXAS WORKFORCE PRESS RELEASE

Manufacturing and Distribution Consortium Partners with North Lake College for $407,230 Job-Training Grant

AUSTIN ⎯ A Manufacturing and Distribution Consortium has partnered with North Lake College to provide job training using a $407,230 Skills Development Fund grant from the Texas Workforce Commission (TWC). The grant will benefit workers in the Workforce Solutions for North Central and Greater Dallas areas.

AUSTIN ⎯ A Manufacturing and Distribution Consortium has partnered with North Lake College to provide job training using a $407,230 Skills Development Fund grant from the Texas Workforce Commission (TWC). The grant will benefit workers in the Workforce Solutions for North Central and Greater Dallas areas.

This grant will be used to provide customized training to 174 new and incumbent workers for industry-related topics with focused instruction on thermoforming, hydraulics and pneumatics, industrial electrical systems, and business logistics. Trainees will include inventory control clerks, warehouse associates, fabrication operators, tooling technicians, distribution coordinators, quality engineers and purchasing agents. Upon completion of training, the workers will receive an average wage of $16.69.

On January 25, 2017, TWC Chairman Andres Alcantar made a $407,230 Skills Development Fund Grant check presentation to representatives from North Lake College and partnering businesses. Pictured from left: Crawford Electric Supply Learning & Development Manager Renee Blaylock, Hagans Plastics President Dennis Hagan, Chairman Alcantar, Hagans Plastics Director of Sales & Marketing Jim Arnet, Owens & Minor Distributing General Manager Chris Wroblewski, Crawford Electric Supply Regional Vice President Kelly Johns, and North Lake College President Christa Slejko.

Nolan Catholic School

At Hagans Plastics, we believe in giving back to the community as well educating for the future. We are pleased to be a sponser of A Robotics Competition named Robo Vikes. Our sponsored school is Nolan Catholic School. Here the students not only work on the design and manufacturing of the robot, they learn to work together as part of a manufacturing company with their own internal sections of Sales and Marketing, Design, Manufacturing, Engineering and Management. They are working on building Leaders for the Future.

Video Link: Nolan Catholic High School – RoboVikes